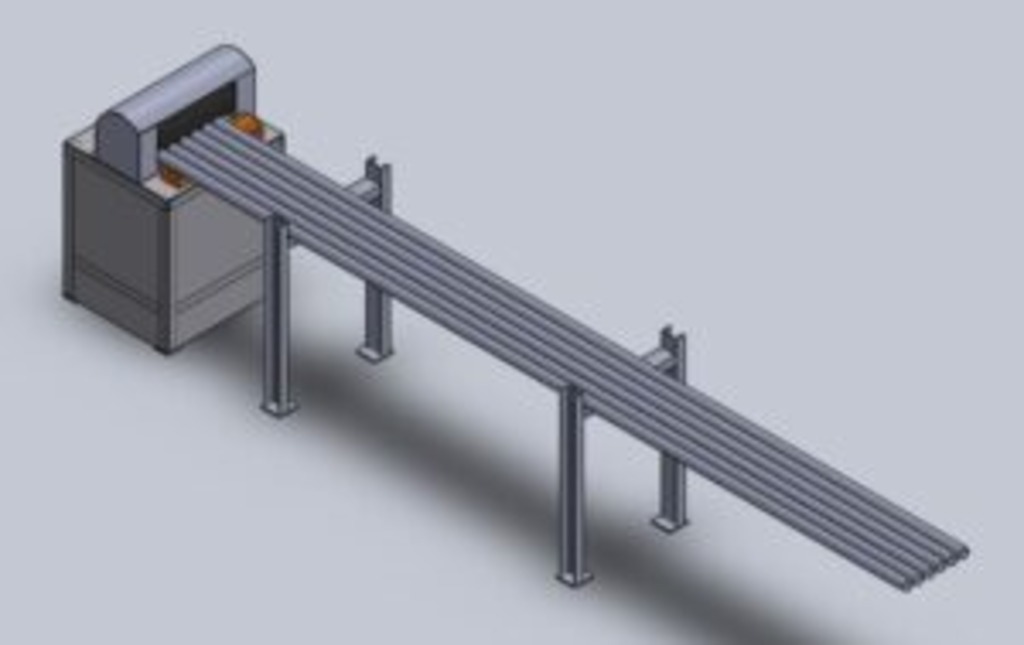

Deburring Machine

We are a leading company dedicated to empowering individuals to achieve their dreams through innovative solutions and exceptional services.

A deburring machine is a specialized industrial tool used to remove burrs, sharp edges, and excess material from metal, plastic, or other workpieces after they have been machined or processed. Burrs are undesirable rough edges or projections that can occur during cutting, drilling, milling, or other manufacturing operations. Removing these burrs is essential to ensure the safety, functionality, and aesthetic appeal of the final product.

Visually, a deburring machine typically features a sturdy frame with a work area where the workpieces are processed. Depending on the specific model and application, deburring machines can vary in size from compact benchtop units to large-scale industrial machines. They may utilize different technologies and methods to achieve effective deburring, such as mechanical, abrasive, thermal, or chemical processes.

The operation of a deburring machine involves placing the workpiece into the machine’s designated area, where it undergoes a controlled deburring process.

Deburring machines are utilized across a wide range of industries, including automotive manufacturing, aerospace, electronics, medical device manufacturing, and precision engineering. They play a crucial role in improving the quality and functionality of components by removing imperfections that could affect performance, assembly, or product lifespan.

In summary, a deburring machine is an indispensable tool in modern manufacturing processes, ensuring that machined parts and components meet stringent quality standards by effectively removing burrs and sharp edges, thereby enhancing safety, reliability, and overall product aesthetics.