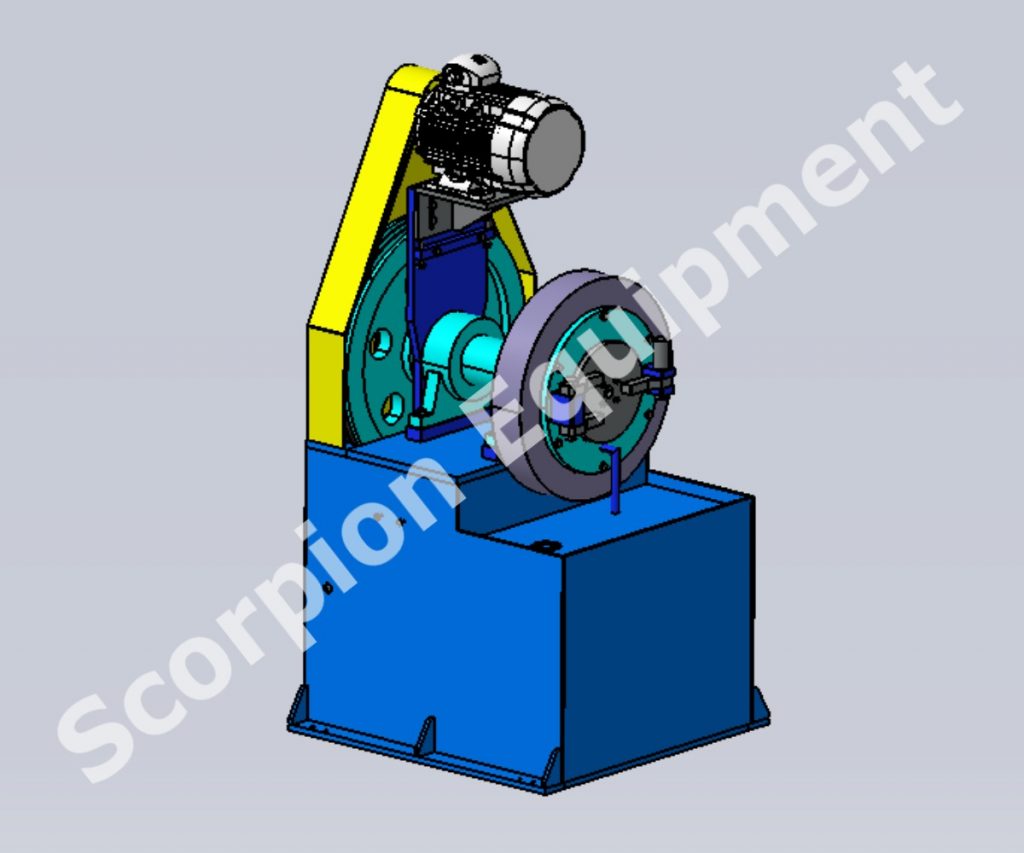

Rotary Swagging Machine

We are a leading company dedicated to empowering individuals to achieve their dreams through innovative solutions and exceptional services.

A rotary swagging machine is a specialized industrial tool used primarily for shaping and forming the ends of metal tubes or pipes through a rotary motion. Unlike traditional swagging machines that typically use a linear press or hydraulic mechanism, rotary swagging machines employ a rotating motion to achieve their shaping effect.

Visually, a rotary swagging machine consists of a robust frame housing a central spindle or mandrel around which the metal tube or pipe is fed. The spindle rotates at high speed, and as the tube or pipe passes through the machine, it undergoes controlled deformation through the action of specialized rollers or dies.

These rollers or dies are strategically positioned around the circumference of the tube or pipe, applying pressure evenly as the rotary motion progresses. This process allows for precise shaping of the material, often creating tapered or expanded sections at the ends of the tube or pipe.

Rotary swagging machines are known for their efficiency and versatility in producing accurately shaped metal components. They are commonly used in industries such as automotive manufacturing, aerospace, HVAC (heating, ventilation, and air conditioning), and plumbing. Applications include forming joints, connectors, or fittings where secure and seamless integration of metal components is essential.

Overall, the rotary swagging machine’s ability to combine rotational movement with precise shaping capabilities makes it a valuable tool in modern manufacturing processes, contributing to enhanced productivity and the production of high-quality metal parts.